An article published this Thursday (3) in the magazine Device reveals a new use for lunar dust: the manufacture of solar cells. In addition to extracting oxygen and titanium, building shelters and creating a cemetery material known as lunarcret, now lunar regolitis can also be used to generate electricity.

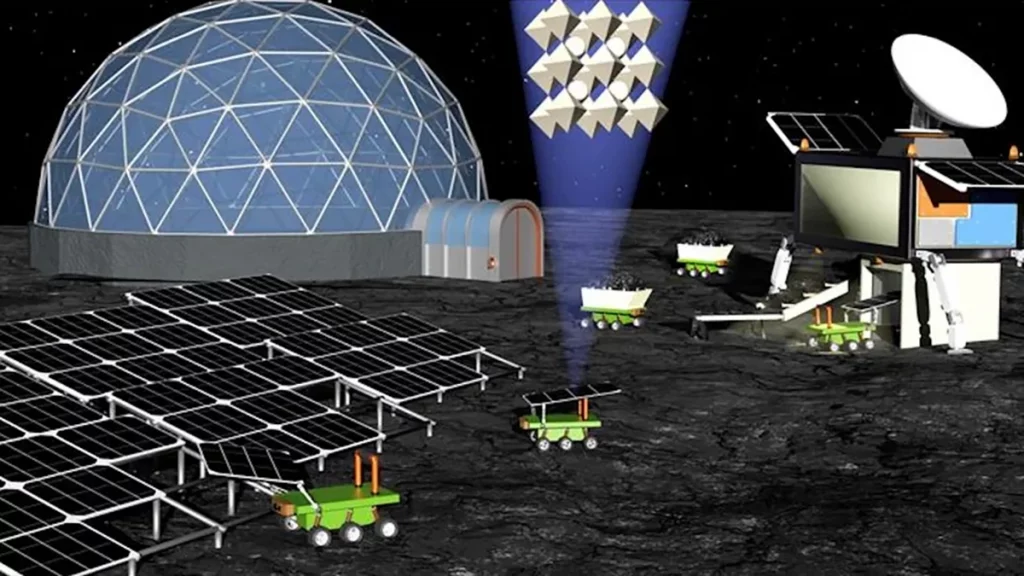

Directed by Felix Lang of the University of Potsdam, Germany, the research suggests that the conversion of lunar dust into solar cells can provide energy to future bases on the Moon. “We already use Regoito to extract water and make bricks. We can now convert it into solar cells, guaranteeing electricity in a lunar city,” Lang said in a statement.

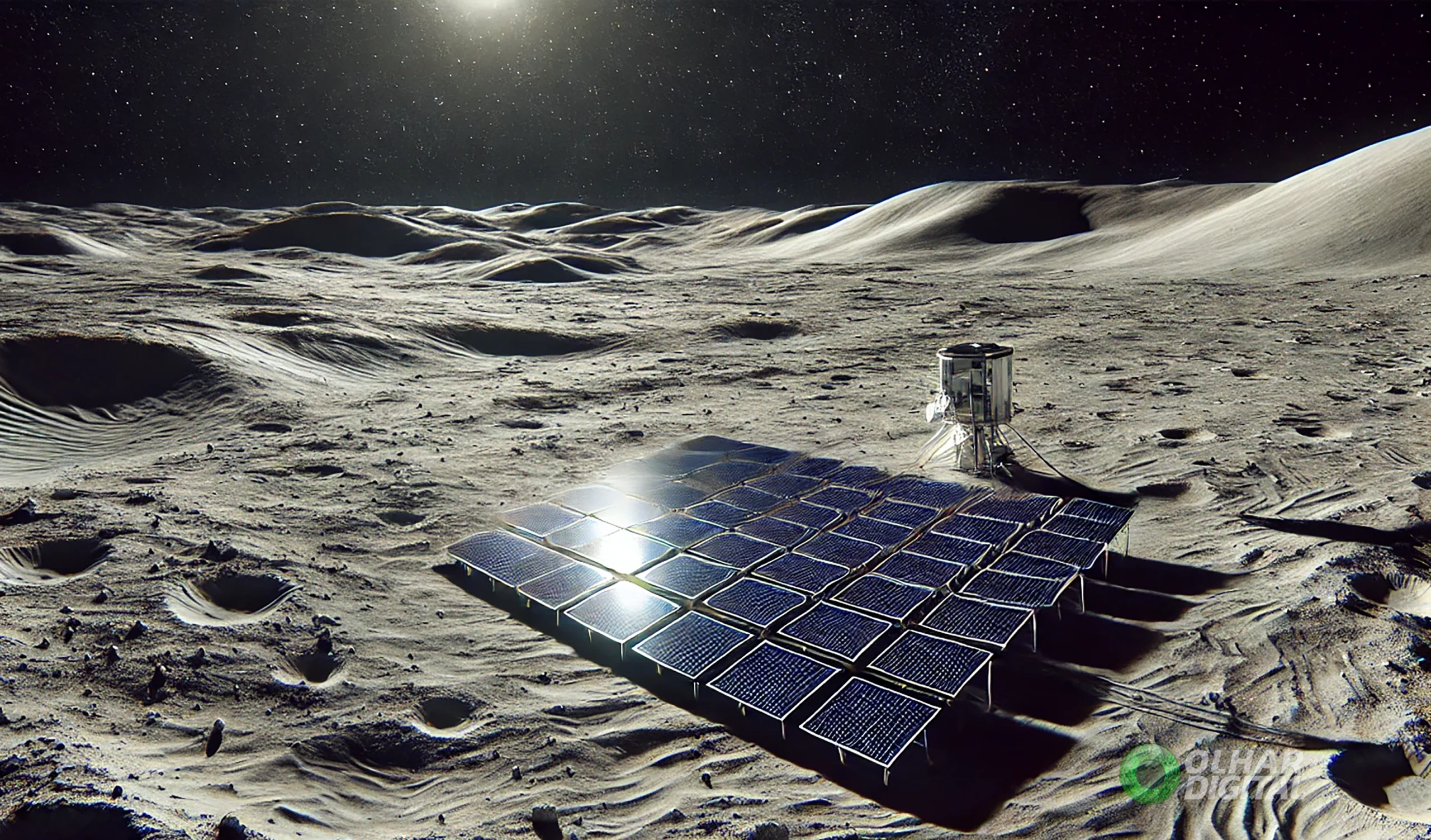

Currently, conventional solar cells use earth glass, a heavy material that makes space missions more expensive. Produce them directly to the Moon, with functions available in the lunar floor, can reduce costs and facilitate the construction of satellite energy infrastructure.

The team uses a lunar dust simulator to produce glass

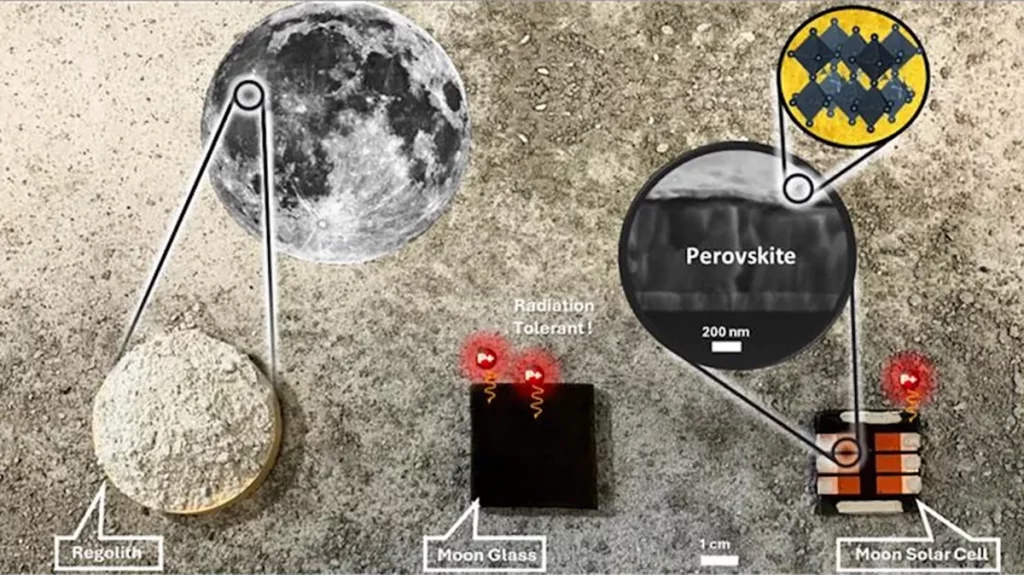

To test this possibility, the Lang team used a lunar dust simulator, as the authentic moon samples are rare and valuable. The simulated regolit was provided by a NASA laboratory, which develops different types of this material for scientific experiments. The regoito has been fused to form lunar glass, a process that can be performed with only concentrated sunlight to reach high temperatures.

Lunar glass is combined with Perovskita, a crystalline material widely used in solar cells. Perovskita absorbs sunlight, releasing electrons captured by an electrode, generating electric current.

It Moons – Name given to lunar glass: It has some advantages on the common glass used on the earth. While traditional glass tends to darke Moons It already has a natural brown color due to the impurities of the regolito. This prevents it from darkening further and compromises the capture of light. In addition, it is more resistant to radiation, a critical factor in the lunar environment, where space particles in space are constantly bombing the surface.

However, solar cells made of lunar glass still do not reach the same efficiency as conventional. While solar panels used in space become between 30% and 40% of sunlight in electricity, produced with Moons They only reach 10%. The Lang team believes that this index can reach 23% by eliminating some impurities of lunar glass.

Read -Ne More:

Energy production on the moon is a challenge

Although efficiency is low, the solution can be viable. “We do not need solar cells with 30% efficiency. Only do -s further on the moon,” Lang explained. In addition, the construction of solar cells directly to the natural satellite significantly reduces the need to transport terrestrial materials, reducing the weight of the sent load by 99%.

There are still technical challenges to overcome. The creation of solar cells of lunar powder simulated in terrestrial gravity is one thing; Doing this in low gravity is different. The team must also verify that the solvents used in the process resist spatial vacuum and if extreme temperature variations on the moon affect cell stability.

To answer these questions, researchers propose an experimental mission to the moon to test solar cells in real conditions. If technology proves to be effective, it can make a sustainable lunar base viable, especially in the southern pole of the Moon, where there are live gel and sunlight. This would prevent the long 14 -day lunar nights, a challenge for conventional solar systems.